ASM 4.7 HEADERS

GranTurismo 4.7 MC Shift

The factory exhaust manifolds on the Maserati M139 and M145 platforms are a known bottleneck. Constructed with restrictive short-radius bends massive dents and prone to heat-induced stress cracking, the OEM units stifle the Ferrari-derived V8’s potential.

The AS Motorsport Longtube Manifold system is the result of extensive R&D, designed to transform the power delivery of your Maserati while solving the flow issues inherent in the stock design.

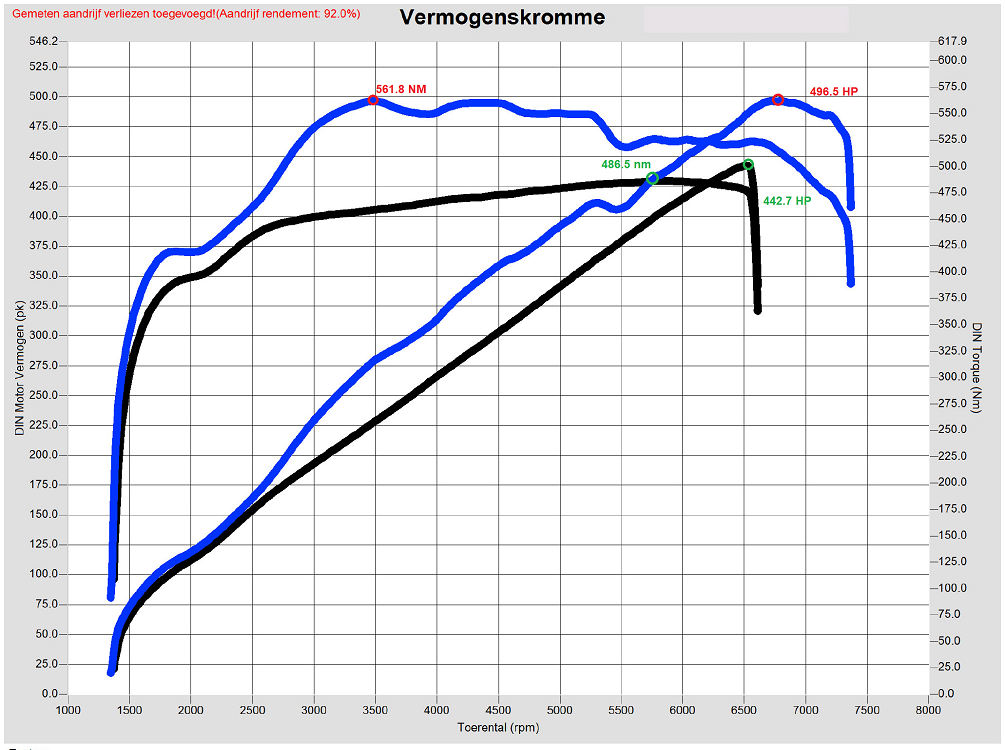

Performance: Torque Where You Need It

While many tuners chase peak horsepower figures at the redline, we have focused our engineering on the 2,500 – 5,000 RPM range. This is where 90% of spirited road driving occurs. By optimizing exhaust scavenging through equal-length primaries, we have achieved a substantial increase in mid-range torque, providing a more immediate throttle response and effortless acceleration in everyday conditions.

Technical Excellence & Manufacturing

- Billet Flanges with Integrated Velocity Stacks: Unlike stamped flanges, our units are CNC-machined from solid stainless steel billets. They feature precision-engineered velocity stacks that provide a smooth transition from the oval exhaust ports to the round primary tubes, minimizing turbulence at the point of highest velocity.

- 3D-Printed Stainless Steel Collectors: We utilize additive manufacturing to create complex internal geometries impossible with traditional welding. Our collectors feature a central "spike" to merge exhaust pulses with laminar flow precision, significantly improving scavenging efficiency.

- True Equal-Length Design: Every primary runner is calculated to ensure exhaust pulses reach the collector at perfectly timed intervals, maximizing the vacuum effect to pull spent gases out of the combustion chamber.

- Superior Durability: The primary tubes are recessed into machined grooves within the flange before TIG welding. This creates a significantly larger surface area for the bond, eliminating the common cracking issues seen at the flange-to-pipe junction on factory headers.

Proven Reliability

Engineering theory is nothing without validation. This system has undergone 30,000 km of real-world testing across various climates and driving conditions—from high-speed motorway touring to intensive track sessions—to ensure long-term structural integrity and performance consistency.

Installation & Requirements

- Compatibility: Designed to mate directly with the factory X-pipe or aftermarket equivalents (e.g., Larini).

- ECU Calibration: Due to the significantly increased flow rate and the relocation of the primary O2 sensors to the high-efficiency collectors, a mandatory ECU retune is required. This ensures optimal Air-Fuel Ratios (AFR) and allows the engine to fully utilize the improved volumetric efficiency.

- Heat Management: We highly recommend our optional ceramic coating to keep exhaust velocities high and protect the engine bay’s sensitive components (coolant hoses and valve cover gaskets) from radiant heat.